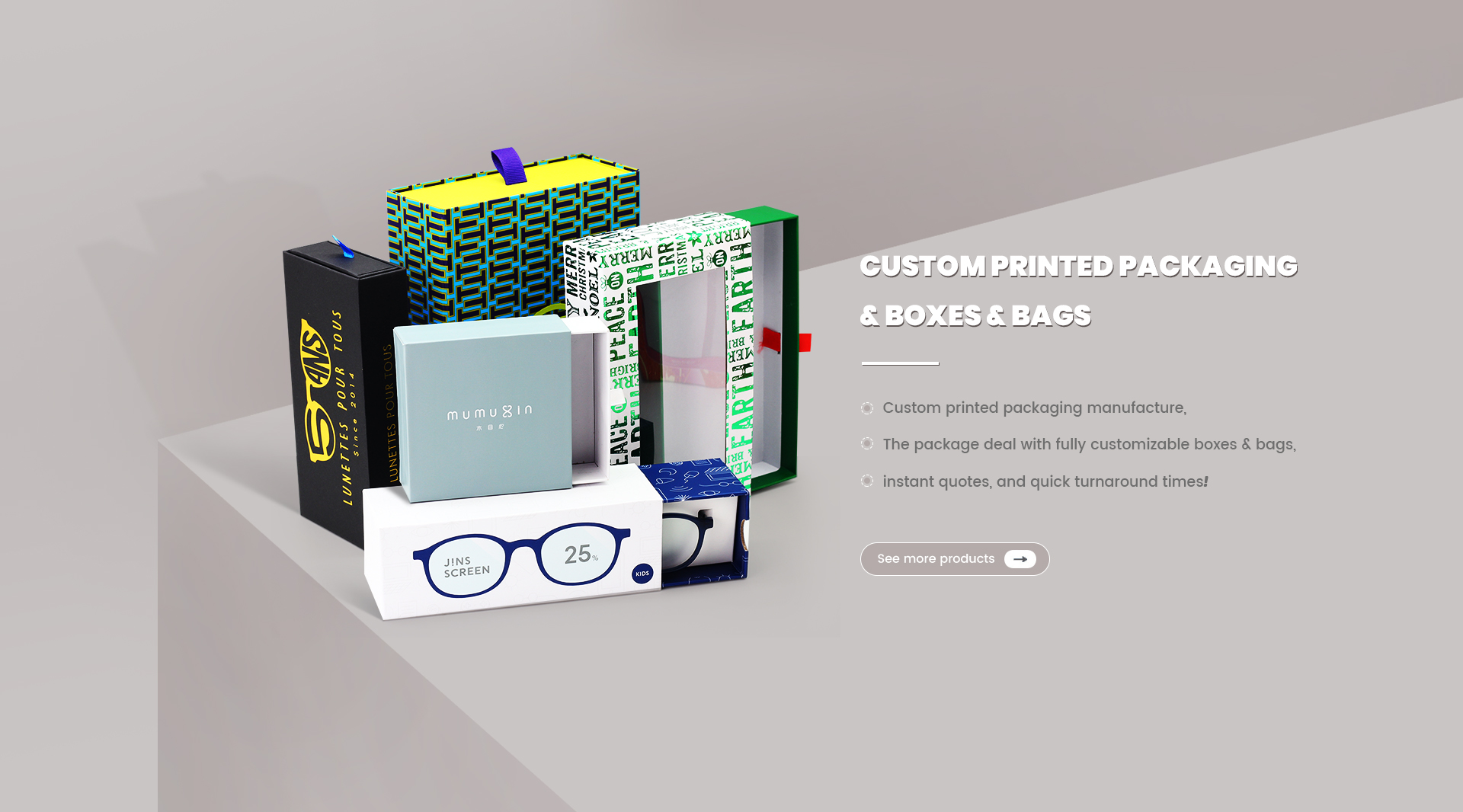

Top OEM Suppliers for Custom Printed Rigid Box Solutions

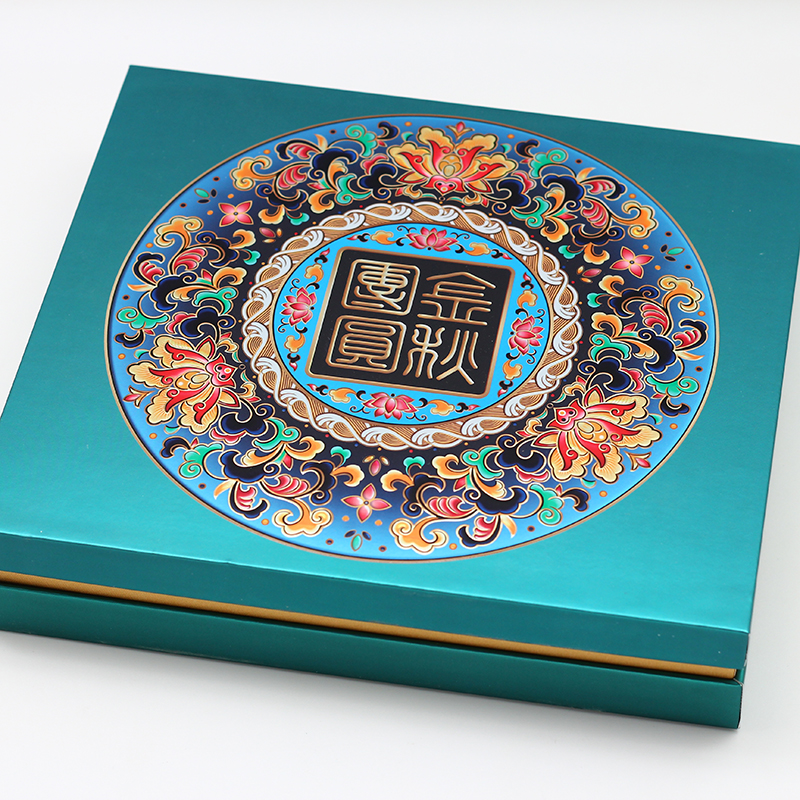

When it comes to packaging solutions, printed rigid boxes are just what I need to elevate my product's presence. These boxes not only provide durability but also allow for stunning custom designs that captivate buyers. As a B2B purchaser, I appreciate working directly with OEM suppliers who understand my unique requirements. The partnership with these suppliers ensures I get quality products that align with my branding strategy. I’ve found that printed rigid boxes are versatile, perfect for luxury items and gifts, offering both style and protection. With various sizes and finishes available, it’s easy to create an impactful unboxing experience. Engaging with reliable suppliers means that I can focus on growing my business while trusting that my packaging needs are in expert hands. If you’re like me and value quality and aesthetics, investing in printed rigid boxes is a decision you won’t regret.

Printed Rigid Box Market Leader Ahead of the Curve

In the rapidly evolving landscape of packaging, printed rigid boxes have emerged as a paramount choice for brands seeking to enhance their product presentation and protect their offerings. This market segment has witnessed growth driven by increasing consumer demand for premium packaging solutions that not only serve practical purposes but also elevate brand appeal. With innovations in design and printing technologies, the printed rigid box market is poised to remain ahead of the curve, meeting the diverse needs of businesses across various sectors. Global procurement managers are increasingly recognizing the value of customized printed rigid boxes as a key element in their branding strategy. These boxes provide not just functionality but also an opportunity for storytelling through compelling designs and high-quality printing. Businesses can leverage these features to attract and retain consumers, creating an emotional connection with their products. As sustainability continues to be a priority, advancements in eco-friendly materials and processes in rigid box manufacturing ensure that companies can meet market expectations while also adhering to environmental standards. As the market for printed rigid boxes evolves, staying ahead of industry trends and consumer preferences is crucial for businesses looking to differentiate themselves. The integration of technology in production processes allows for greater flexibility and personalization, enabling brands to respond swiftly to the dynamic demands of the market. For companies aiming to enhance their packaging strategy, investing in printed rigid boxes not only delivers aesthetic value but also positions them as leaders in their respective industries, ensuring they remain competitive in an increasingly global marketplace.

Printed Rigid Box Market Leader Ahead of the Curve

| Market Segment | Market Share (%) | Growth Rate (CAGR) | Key Trends |

|---|---|---|---|

| Consumer Electronics | 30% | 8% | Sustainability, Customization |

| Luxury Goods | 25% | 7% | Premium Packaging, Aesthetic Appeal |

| Food and Beverage | 20% | 5% | Eco-friendly Materials, Eye-catching Designs |

| Health and Personal Care | 15% | 6% | Focus on Hygiene, Minimalistic Packaging |

| E-commerce | 10% | 9% | Branded Packaging, Shipping Innovations |

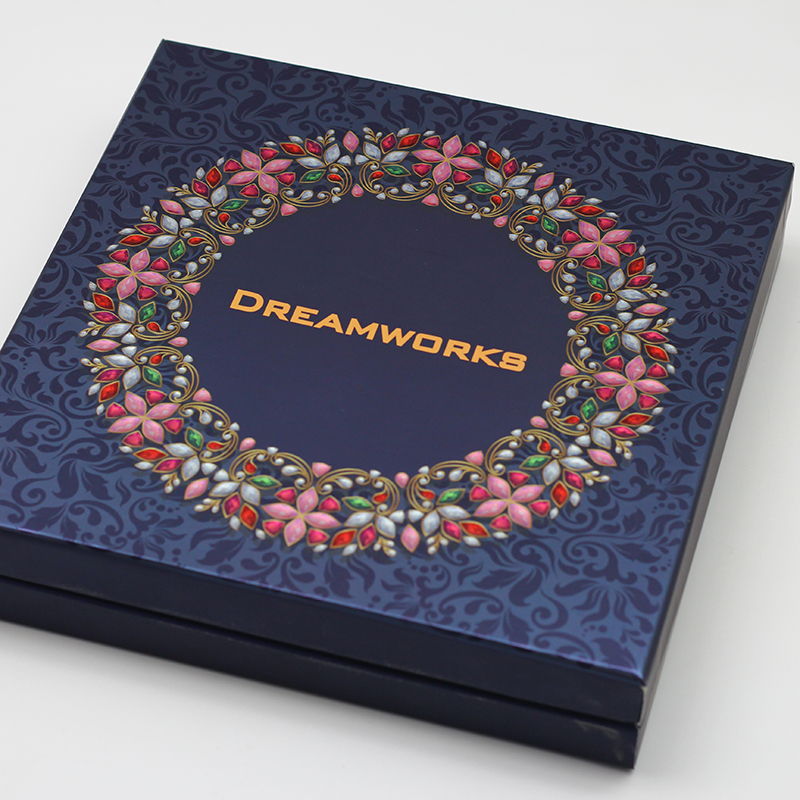

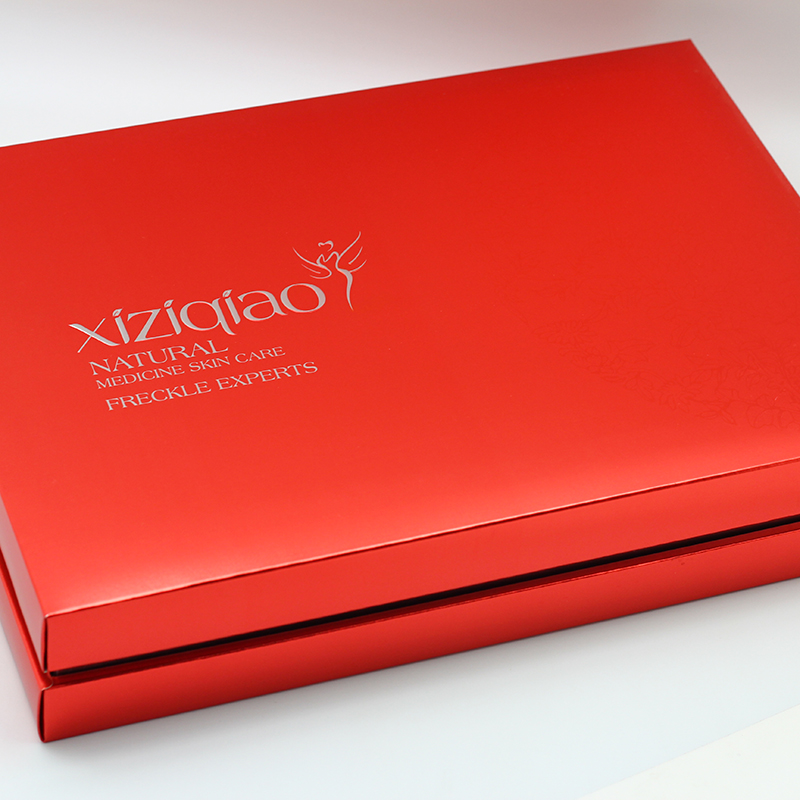

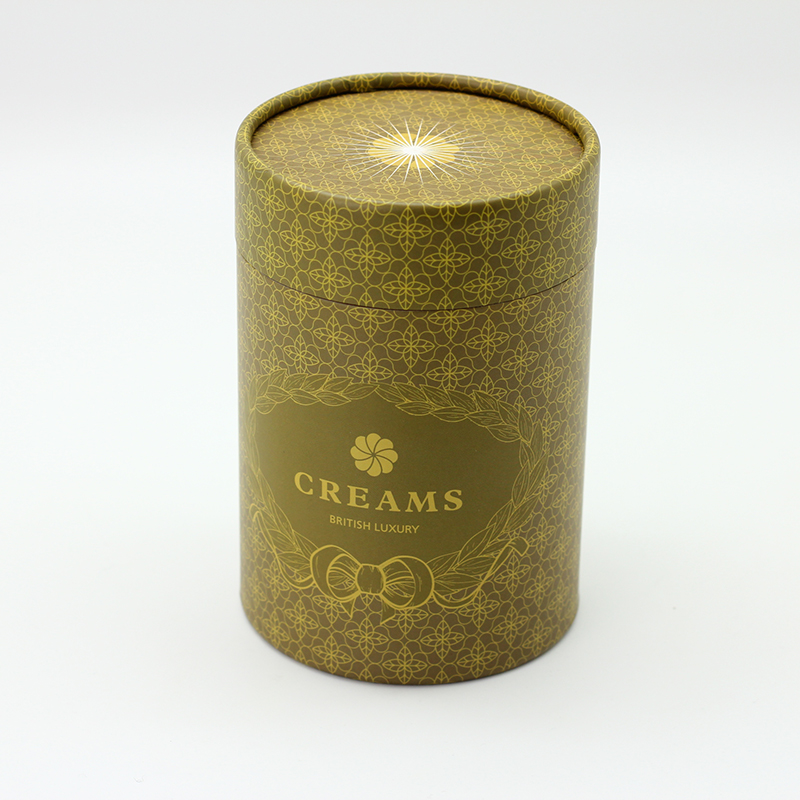

Related Products